Cedar Canopy

Warehouse 4 at the Kettering, Ohio location (3131 Wilmington Pike, 45429.

Early 2020, the crew behind Warehouse 4 began designing their newest location in Kettering, Ohio. As a former bank, the property required a heavy overhaul but did grace a few perks; tall ceilings, a drive-through, parking. The tall ceilings allowed the crew to dream up architectural features that give spicy flavor to new space.

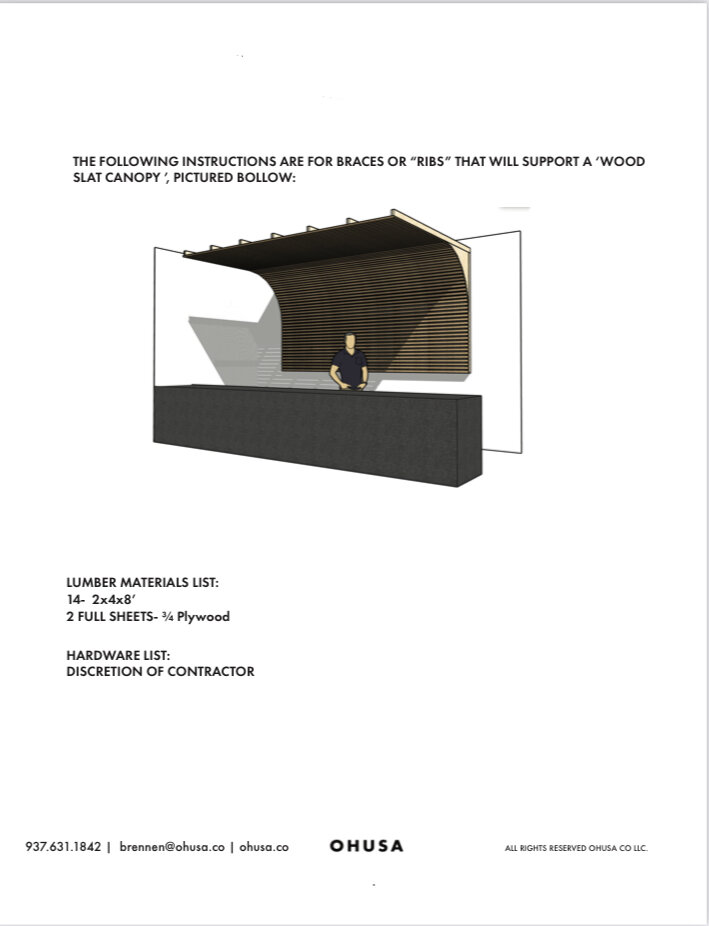

The vision to “cozy up” the ceiling took a few different shapes throughout the build-out. It was the team’s original idea to build a hanging wood feature that would hone focus onto the main event at the shop, the barista bar. Helping to guide this concept, I imagined and took inspiration from the the word “canopy”; something light and airy to break up the air space while giving a sense of comfort and coziness. The canopy would hang over one of my favorite features in the whole shop, the seventeen foot concrete barista bar. This massive feature was built by M Concrete and feels like it was simply extruded from the floor.

With a strong, brutalist anchor below, the canopy needed to completely relieve any heaviness and cold brought into the space. Cedar, in my opinion, was the perfect material to do just this.

A very soft and airy wood, cedar met all the specs needed to defy gravity. Though it is hard to come by half-inch thick, twelve-foot long cedar that is not warped, the most realistic option was to ‘mill’ the material myself. Starting with 2x6x12’ stock lumber, I used a worm-drive circular saw and a rip-fence jig to make the 68 slats needed for the job (not the time to have a battery-powered circ saw). Each slat was sanded, finished with Cabin Walls by Walrus Oil, and bundled to prevent warping.

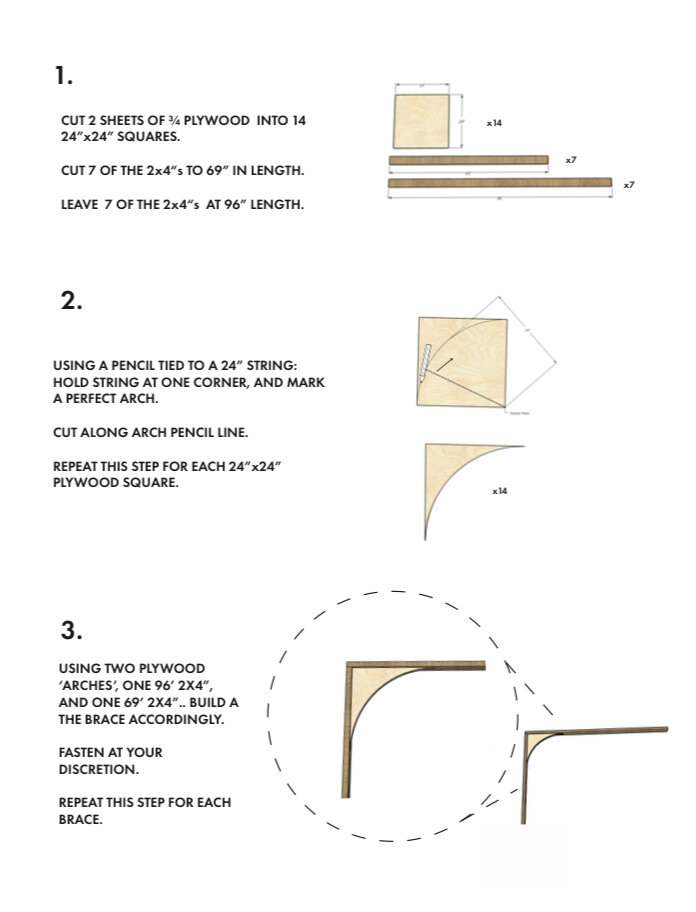

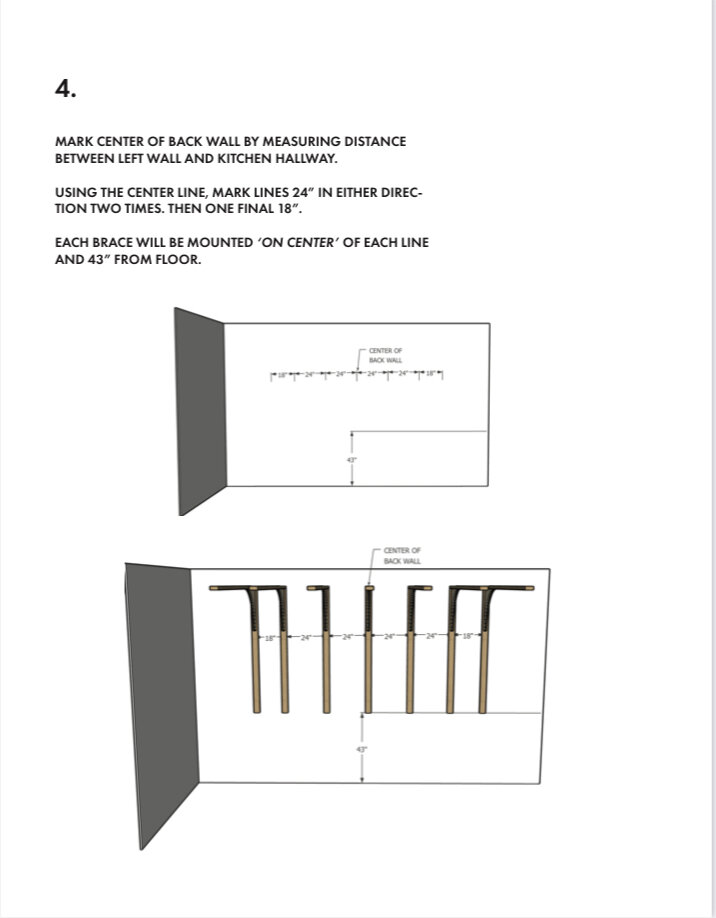

Working in part with the construction team’s carpenter, the basic structure or “ribs” of the canopy is made of 2x4’s and plywood. The step by step instructions walked the contractor through the assembly and the ribs were built and installed in just under a day. When I arrived, the cedar slats just needed to be attached via structural adhesive and 18ga nails. This process required a second pair of hands to help manage the twelve-foot cedar material.

Taking extra care on the first cedar slat to ensure its center and its level, we then used that slat as our reference for alignment. From there, we spaced each slat equally by means of a 3/4” spacer block. Resting spacer blocks on the previous slat, we worked our way right to left glueing and nailing into each “rib”. Ultimately, this process took about two days of work.

The cedar canopy, no doubt, is a feature that stands out particularly because it defies gravity and title wave of a shape. Thankful for the crew behind Warehouse 4’s design and willingness to let OHUSA into their space.

Brennen

Designer & Builder